To be direct, a new YAG (Yttrium Aluminum Garnet) laser cutting machine is one of the most expensive options in the industrial laser market. You should expect prices to start at approximately $200,000 and increase from there based on power, features, and system integration. This high cost is a reflection of its specialized nature and the fact that it represents an older generation of technology.

The critical takeaway is not the high price of a YAG laser, but why it is so expensive. For most modern applications, especially metal cutting, the YAG laser has been largely superseded by more efficient and cost-effective fiber laser technology. Understanding this distinction is key to avoiding a poor investment.

Why YAG Lasers Carry a Premium Price

The six-figure price tag for a YAG laser system is not arbitrary. It's rooted in the technology itself, its specific applications, and its place in the history of laser development.

The Technology: Solid-State but Outpaced

A YAG laser is a type of solid-state laser, where light is generated by exciting a crystal rod (the yttrium aluminum garnet doped with neodymium). This was a significant advancement for its time.

However, modern fiber lasers are also solid-state lasers. They represent the next generation of this technology, offering superior efficiency, reliability, and beam quality for most tasks.

YAG lasers often require expensive and fragile components like flashlamps for pumping the crystal, which have a limited lifespan and add to the operational cost. Fiber lasers use long-lasting laser diodes, dramatically reducing maintenance.

The Rise of the Fiber Laser

For nearly all applications involving metal cutting and general marking, the fiber laser has become the dominant technology.

Fiber lasers generate and deliver the laser beam within a flexible optical fiber, making them more robust, more electrically efficient, and capable of producing a higher-quality beam. This results in faster cutting speeds and lower long-term operating costs.

Because of this, the market for new YAG laser cutting machines has shrunk dramatically, making them a niche, high-cost product.

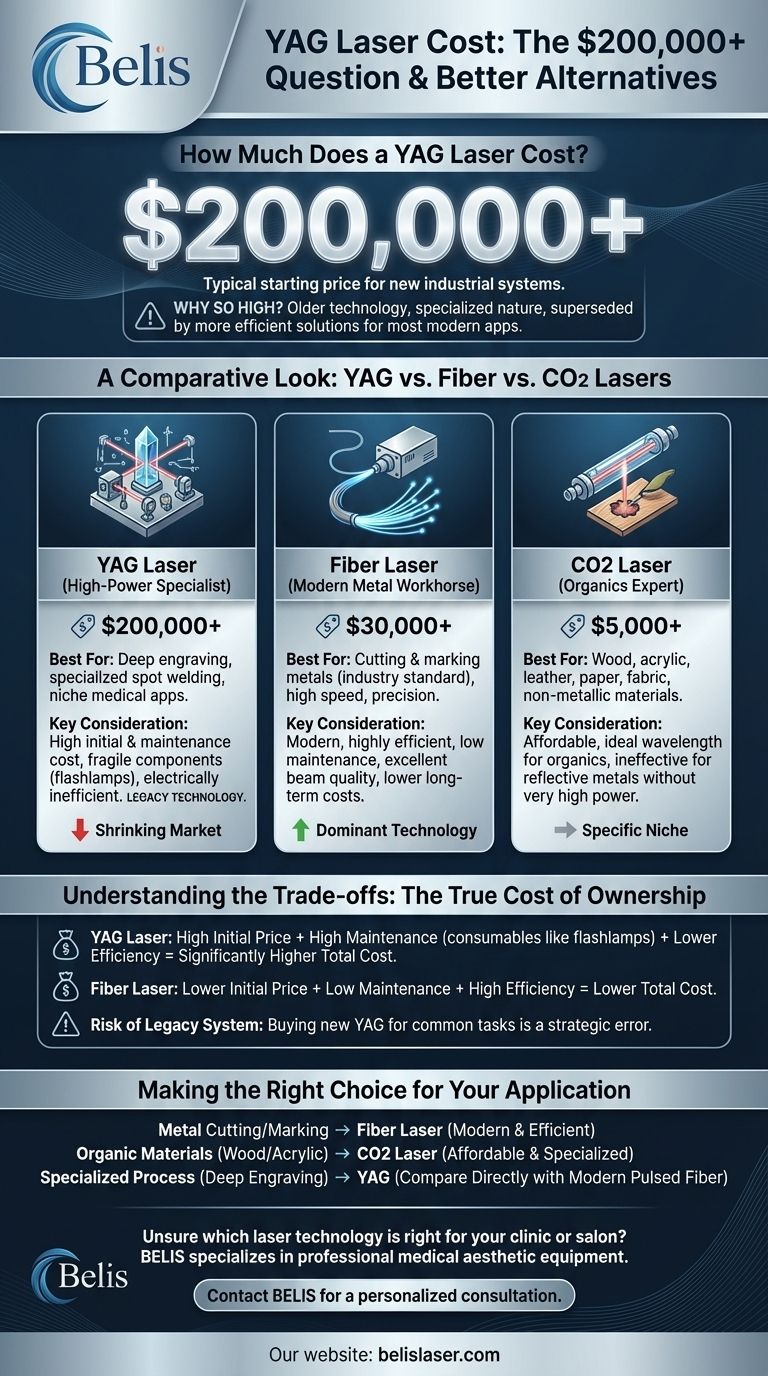

A Comparative Look: YAG vs. Fiber vs. CO2

Understanding where YAG fits requires comparing it to the other main industrial laser types.

YAG Lasers: The High-Power Specialist

These systems excel at producing extremely high peak power in very short pulses. This makes them suitable for specific tasks like deep metal engraving, spot welding, and certain medical applications where this pulse energy is critical. For general cutting, they are inefficient.

Fiber Lasers: The Modern Metal Workhorse

With prices ranging from around $30,000 to well over $100,000, fiber lasers are the current industry standard for processing metals. They offer the best balance of speed, precision, low maintenance, and operational cost for cutting, etching, and marking steel, aluminum, brass, and other metals.

CO2 Lasers: The Organics Expert

Starting as low as a few thousand dollars for entry-level models, CO2 lasers are the go-to for processing non-metallic materials. Their wavelength is ideal for wood, acrylic, leather, paper, and glass. They are generally not effective for cutting reflective metals without very high power levels.

Understanding the Trade-offs

Considering a YAG laser requires a clear-eyed view of its significant downsides for most potential buyers.

The True Cost of Ownership

The initial $200,000+ purchase price is only the beginning. The frequent replacement of consumable parts like flashlamps and the lower electrical efficiency mean the total cost of ownership for a YAG laser is significantly higher than for a modern fiber laser.

A Niche Application Window

Unless your process explicitly requires the unique pulse characteristics of a lamp-pumped YAG laser for a task like deep, high-contrast engraving, you are likely paying a premium for outdated technology.

The Risk of a Legacy System

Investing in a new YAG laser for a common application like sheet metal cutting is often a strategic error. You would be buying a machine that is slower, more expensive to run, and less capable than the current industry-standard fiber laser.

Making the Right Choice for Your Application

Your final decision should be driven entirely by the material you need to process and the task you need to perform.

- If your primary focus is cutting or marking metal: Investigate fiber lasers. They are the more modern, efficient, and cost-effective solution for these tasks.

- If your primary focus is cutting organic materials (wood, acrylic, fabric): Your best choice is a CO2 laser, which is specifically designed for these materials and is far more affordable.

- If your primary focus is a highly specialized industrial process (e.g., deep engraving, spot welding): A YAG laser might be a candidate, but you must perform a direct comparison with a modern pulsed fiber laser, which can often perform the same task more effectively.

Focusing on your specific application, not just the technology type, is the key to making a sound and profitable investment.

Summary Table:

| Laser Type | Typical Starting Price | Best For | Key Consideration |

|---|---|---|---|

| YAG Laser | $200,000+ | Deep engraving, specialized welding | High cost, older technology, high maintenance |

| Fiber Laser | $30,000+ | Cutting & marking metals (industry standard) | Modern, efficient, low operating costs |

| CO2 Laser | $5,000+ | Wood, acrylic, leather, other organics | Not for reflective metals |

Unsure which laser technology is right for your clinic or salon?

BELIS specializes in professional medical aesthetic equipment, helping medical aesthetics clinics and premium beauty salons make the most profitable investment. Our experts will analyze your specific needs to recommend the perfect laser system—whether for advanced skin treatments, hair removal, or other aesthetic applications—ensuring you get superior performance and an excellent return on investment.

Contact BELIS today for a personalized consultation and discover the right laser solution for your business.

Visual Guide

Related Products

- Pico Picosecond Laser Machine for Tattoo Removal Picosure Pico Laser

- Clinic Use IPL and SHR Hair Removal Machine with Nd Yag Laser Tattoo Removal

- Diode Laser SHR Trilaser Hair Removal Machine for Clinic Use

- Clinic Diode Laser Hair Removal Machine with SHR and Trilaser Technology

- Trilaser Diode Hair Removal Machine for Beauty Clinic Use

People Also Ask

- For which applications are Pico lasers considered versatile? A Guide to Elite Skin Restoration

- How does pulse duration influence the design of cooling strategies? Key Engineering Insights for Laser Hair Removal

- Why are high-precision laser parameters used in LADD? Optimize Drug Delivery and Safety with Precision Control

- What are the benefits of picosecond machines? Comparing Picosecond vs Nanosecond Lasers for Tattoo Removal

- What are the benefits of Pico laser machines? Achieve Faster Results and Safer Skin Rejuvenation