In short, yes, but the duration is entirely dependent on the specific YAG laser treatment you receive. Downtime can range from a few hours of mild redness to over a week of significant healing. The deciding factor is whether the laser procedure is designed to be gentle and non-ablative or intensive and ablative.

The term "YAG laser" is not one-size-fits-all, referring to different technologies like Nd:YAG and Er:YAG used for vastly different purposes. The downtime you experience is directly tied to whether the laser targets deeper tissue without breaking the skin's surface or intentionally removes the outer layer of skin.

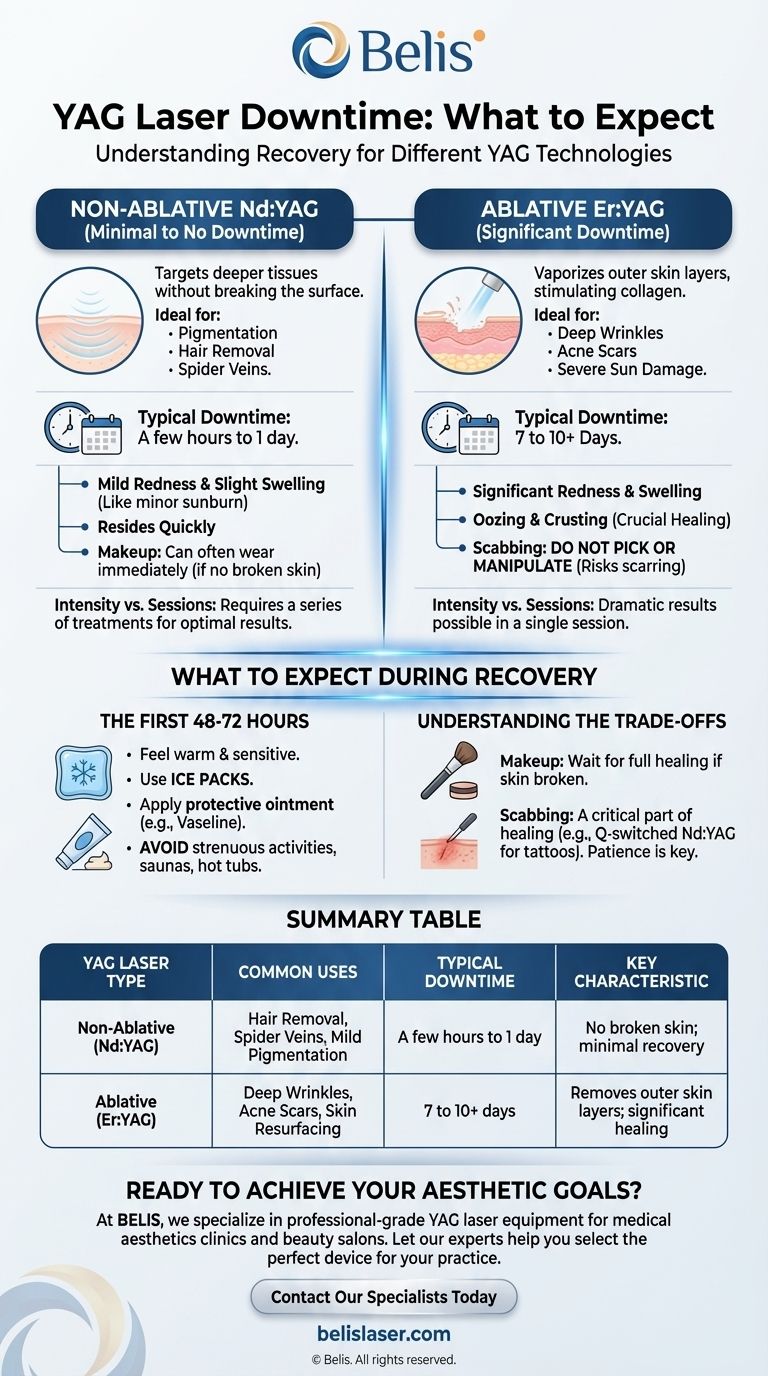

The Two Worlds of YAG Lasers

Understanding the type of YAG laser being used is the key to anticipating your recovery. They fall into two main categories: non-ablative (no broken skin) and ablative (skin is removed).

Non-Ablative Nd:YAG: Minimal to No Downtime

Non-ablative Nd:YAG lasers are commonly used for treating pigmentation, unwanted hair, or spider veins.

The laser's energy passes through the skin's surface to target deeper structures like hair follicles or pigment. Because the epidermis (top layer of skin) remains intact, the recovery is minimal.

You can typically expect mild redness and slight swelling, similar to a minor sunburn, which usually subsides within a few hours to a day.

Ablative Er:YAG: Significant Downtime

Ablative Erbium:YAG lasers are used for aggressive skin resurfacing to treat deep wrinkles, acne scars, and severe sun damage.

This laser works by vaporizing the outer layers of skin, which stimulates a powerful collagen-rebuilding response. This process necessitates a true healing period.

Recovery involves significant redness, swelling, and often oozing or crusting for several days. Social downtime is typically 7-10 days before the skin is healed enough for you to resume normal activities comfortably.

What to Expect During Recovery

Your post-treatment experience is a direct result of the treatment's intensity.

The First 48-72 Hours

Immediately after most YAG procedures, the treated area will feel warm and sensitive. Your provider will likely apply a cooling compress or recommend using ice packs at home to manage swelling.

For any treatment that breaks the skin, you will need to keep the area clean and apply a protective ointment, such as Vaseline or an antibiotic ointment, to create a barrier and promote healing.

Activity Restrictions

It is standard advice to avoid strenuous activities, saunas, and hot tubs for 48-72 hours after almost any laser treatment.

Increasing your heart rate and body temperature can worsen swelling and inflammation, potentially prolonging your recovery.

Understanding the Trade-offs

Choosing a laser treatment involves balancing the desired outcome with the required recovery time.

The "Makeup Immediately" Rule

The ability to wear makeup immediately only applies to truly non-ablative treatments where the skin's surface has not been broken. If you experience any pinpoint bleeding, blistering, or scabbing, you must wait until the skin is fully healed to apply cosmetics to avoid infection and irritation.

The Reality of Scabbing

If a scab forms, it is a critical part of the healing process. This is common with Q-switched Nd:YAG for tattoo removal or ablative Er:YAG resurfacing.

It is absolutely crucial that you do not pick or manipulate the scab. Doing so can lead to permanent scarring or post-inflammatory hyperpigmentation (dark spots), compromising your final result.

Intensity vs. Number of Sessions

Gentle, no-downtime procedures almost always require a series of treatments spaced several weeks apart to achieve the final goal. More aggressive, high-downtime procedures can often deliver a more dramatic result in a single session.

Making the Right Choice for Your Goal

Your personal tolerance for downtime is as important as the clinical outcome you seek.

- If your primary focus is addressing hair or mild pigment with minimal life disruption: A non-ablative Nd:YAG is suitable, but plan for a series of appointments to achieve your result.

- If your primary focus is removing a tattoo: Expect a few days of localized healing with a Q-switched Nd:YAG, as blistering and scabbing are part of the process.

- If your primary focus is dramatic skin resurfacing for wrinkles or scars: Schedule an ablative Er:YAG procedure when you can commit to at least one full week of dedicated recovery at home.

Ultimately, a clear conversation with your provider about the specific device being used will empower you to plan your recovery with confidence.

Summary Table:

| YAG Laser Type | Common Uses | Typical Downtime | Key Characteristic |

|---|---|---|---|

| Non-Ablative (Nd:YAG) | Hair Removal, Spider Veins, Mild Pigmentation | A few hours to 1 day | No broken skin; minimal recovery |

| Ablative (Er:YAG) | Deep Wrinkles, Acne Scars, Skin Resurfacing | 7 to 10+ days | Removes outer skin layers; requires significant healing |

Ready to Achieve Your Aesthetic Goals with Minimal Disruption?

Choosing the right laser technology is crucial for achieving optimal results while managing recovery time. At BELIS, we specialize in providing medical aesthetics clinics and premium beauty salons with professional-grade YAG laser equipment.

Our experts can help you select the perfect device for your practice's needs, whether you focus on quick, no-downtime treatments or more intensive resurfacing procedures.

Let us help you enhance your service offerings and client satisfaction.

Contact our specialists today to discuss how our medical aesthetic equipment can drive your business growth.

Visual Guide

Related Products

- Clinic Use IPL and SHR Hair Removal Machine with Nd Yag Laser Tattoo Removal

- Pico Picosecond Laser Machine for Tattoo Removal Picosure Pico Laser

- Clinic Use IPL SHR ND YAG Laser Hair Removal RF Skin Tightening Machine

- Diode Laser SHR Trilaser Hair Removal Machine for Clinic Use

- Trilaser Diode Hair Removal Machine for Beauty Clinic Use

People Also Ask

- What are the recommended laser parameters for effective and safe skin ablation? Master Er:YAG Precision

- How do ND: YAG lasers address pigmentation concerns? Advanced Laser Solutions for Radiant, Spot-Free Skin

- How does the Q-switched Nd:YAG laser system function in the treatment of solar lentigines? Learn the Science of Pigment Removal

- Why is Q-switched technology essential for the selective removal of dermal melanin? Precision Pigment Shattering

- How does a long-pulsed 1064nm Nd:YAG laser treat keloid scars? Starve Scar Growth with Targeted Vascular Destruction

- What is the core function of high-power Q-switched technology in the removal of benign pigmented lesions? Explained

- What are the advantages of Long-pulsed 1064nm & IPL for PWS? Optimize Port Wine Stain Clearance

- How does a Q-switched Nd:YAG laser work for tattoo removal? Advanced Ink Shattering Technology Explained