At its core, a laser machine is a highly versatile tool that uses a concentrated beam of light to precisely cut, engrave, mark, or otherwise alter a material's surface. Unlike traditional mechanical tools, it performs its work without physical contact, enabling intricate designs and clean finishes on a vast range of materials.

A laser machine's primary purpose is to apply focused energy with extreme precision. This allows for complex manufacturing and design tasks that are often impractical or impossible to achieve with conventional tools, minimizing material waste and damage.

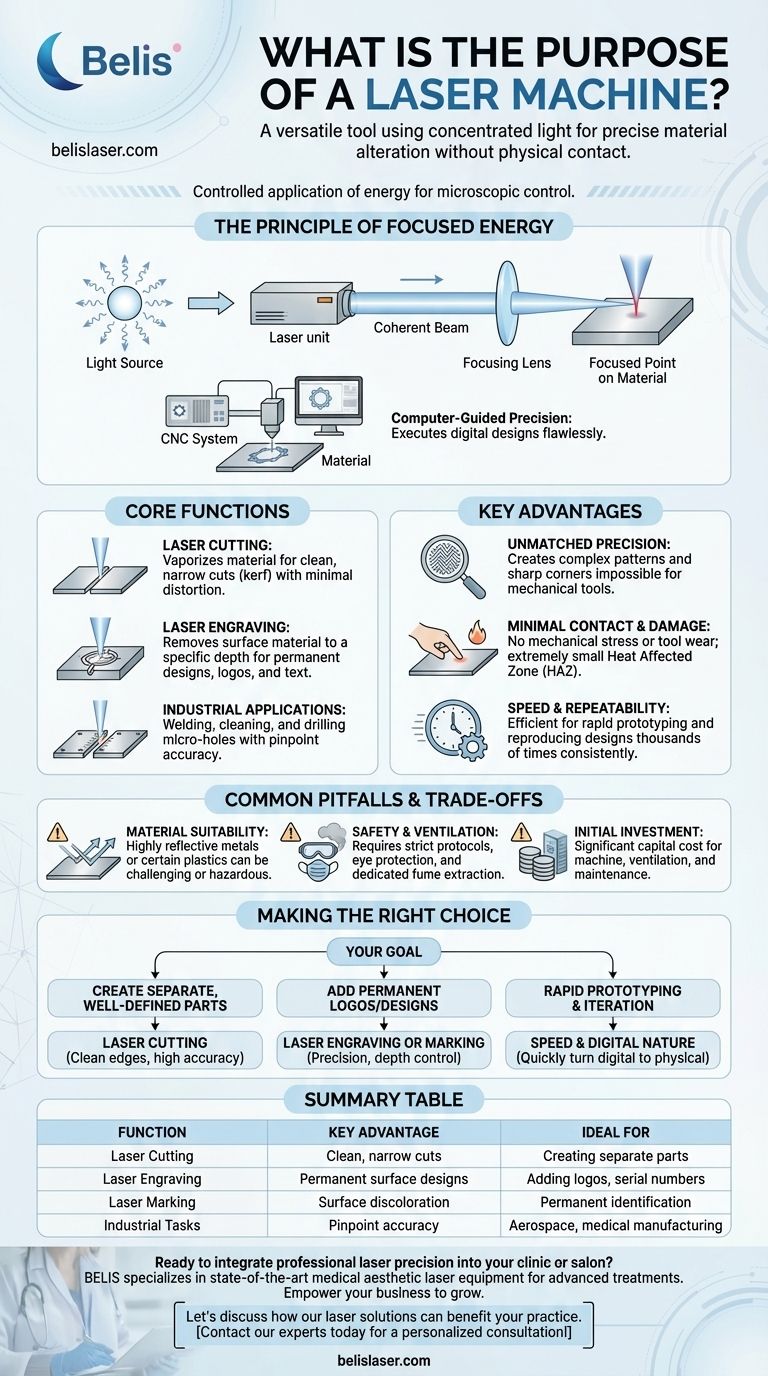

The Principle of Focused Energy

To understand the purpose of a laser, you must first understand its fundamental principle: the controlled application of energy. A laser machine isn't just a powerful light; it's a complete system designed for microscopic control.

From Light to a Coherent Beam

A laser machine generates a beam of light where all the photons move in a single, organized direction. This coherent light is the source of its power and can be focused with incredible accuracy.

The Role of the Focusing Lens

This coherent beam is directed through a lens that concentrates all of its energy into a single, tiny point. This concentration of energy is what gives the laser its ability to instantly vaporize or melt the material it touches.

Computer-Guided Precision

The laser head is mounted on a computer numerical control (CNC) system. This system translates a digital design into precise X and Y coordinates, guiding the laser point across the material to execute the design flawlessly and repeatably.

Core Functions: Cutting, Engraving, and More

While people often associate lasers with cutting, their capabilities are much broader. The machine's function is determined by how it's programmed to apply its power.

Laser Cutting

For cutting, the laser beam is set to a high power level that allows it to vaporize the material completely as it moves. This creates an exceptionally clean and narrow cut line, known as the kerf, with minimal burning or distortion.

Laser Engraving and Marking

For engraving, the laser operates at a lower power. Instead of cutting all the way through, it removes only the top surface of the material to a specific depth, creating permanent designs, logos, or text. Marking is an even lower-power process that often just discolors the surface without removing material.

Industrial Applications

Beyond these common uses, industrial lasers perform critical tasks like welding metals with pinpoint accuracy, cleaning delicate surfaces by ablating contaminants, and drilling micro-holes in aerospace and medical components.

Understanding the Key Advantages

The reason laser machines are so prevalent in modern industry comes down to a few key advantages over traditional methods.

Unmatched Precision

Lasers can create incredibly intricate patterns and sharp corners that are impossible for mechanical cutting tools. This allows for the production of complex components, from delicate jewelry to precise circuit boards.

Minimal Material Contact and Damage

Because only a beam of light touches the material, there is no mechanical stress, material drag, or tool wear. Furthermore, the energy is so focused that the surrounding area, known as the Heat Affected Zone (HAZ), is extremely small. This minimizes the risk of warping or deformation, which is critical for sensitive materials.

Speed and Repeatability

Once a design is programmed, a laser machine can reproduce it thousands of times with perfect consistency. The high speed of the laser head makes it an efficient tool for both rapid prototyping and full-scale production runs.

Common Pitfalls and Trade-offs

While powerful, laser machines are not a universal solution. Understanding their limitations is key to using them effectively.

Material Suitability

Not every material reacts to a laser in the same way. Highly reflective metals, like raw copper or silver, can be difficult to cut as they bounce much of the laser's energy away. Certain plastics can produce hazardous fumes and require specialized ventilation.

Safety and Ventilation

Laser machines are powerful tools that require strict safety protocols. The intense light can cause permanent eye damage, and the vaporization of materials can release toxic fumes. Proper shielding and a dedicated ventilation system are non-negotiable.

Initial Investment

Professional-grade laser systems represent a significant capital investment. The cost of the machine, ventilation, and ongoing maintenance must be factored into any decision to adopt the technology.

Making the Right Choice for Your Goal

The specific laser process you use should be directly aligned with your end goal.

- If your primary focus is creating separate, well-defined parts from a sheet of material: You need laser cutting for its ability to produce clean edges with high accuracy.

- If your primary focus is adding permanent logos, serial numbers, or artistic designs to a surface: You need laser engraving or marking for its precision and control over depth.

- If your primary focus is rapid prototyping and design iteration: The speed and digital nature of a laser machine make it ideal for quickly turning digital concepts into physical objects.

Ultimately, a laser machine transforms a digital design into a physical reality with unparalleled precision and control.

Summary Table:

| Function | Key Advantage | Ideal For |

|---|---|---|

| Laser Cutting | Clean, narrow cuts with minimal distortion | Creating separate parts from sheet materials |

| Laser Engraving | Permanent surface designs with controlled depth | Adding logos, serial numbers, artistic details |

| Laser Marking | Surface discoloration without material removal | Permanent identification and branding |

| Industrial Tasks | Pinpoint accuracy for welding, cleaning, drilling | Aerospace, medical, and high-precision manufacturing |

Ready to integrate professional laser precision into your clinic or salon?

BELIS specializes in providing state-of-the-art medical aesthetic laser equipment to help you offer advanced, high-quality treatments. Our machines are designed for reliability, ease of use, and exceptional results, empowering your business to grow.

Let's discuss how our laser solutions can benefit your practice.

Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Fractional CO2 Laser Machine for Skin Treatment

- Pico Picosecond Laser Machine for Tattoo Removal Picosure Pico Laser

- Cryolipolysis Fat Freezing Cavitation Lipo Laser Machine

- Cryolipolysis Fat Freezing Machine Cavitation Lipo Laser Machine

- Cryolipolysis Fat Freezing Machine with Cavitation and Laser Lipolysis

People Also Ask

- What does a CO2 laser do to your face? Achieve Profound Skin Resurfacing & Renewal

- How often should you do fractional CO2 laser? The 4-6 Week Rule for Optimal Results

- Who is not a good candidate for CO2 laser? Avoid Complications and Ensure Safe Treatment

- What will my face look like after a CO2 laser? Your Complete Recovery Timeline

- What is a fractional CO2 laser machine used for? A Guide to Advanced Skin Resurfacing