In any fluid system, cavitation is a destructive force that should be engineered out of the design or carefully managed during operation. Its primary drawbacks are severe component damage through material erosion, significant loss of operational efficiency, and the creation of intense noise and vibration that can compromise the entire system's integrity.

The core danger of cavitation is not the formation of vapor bubbles in a low-pressure zone, but their violent and instantaneous collapse when they travel into a higher-pressure region. This collapse unleashes concentrated bursts of energy that act like microscopic hammer blows against component surfaces.

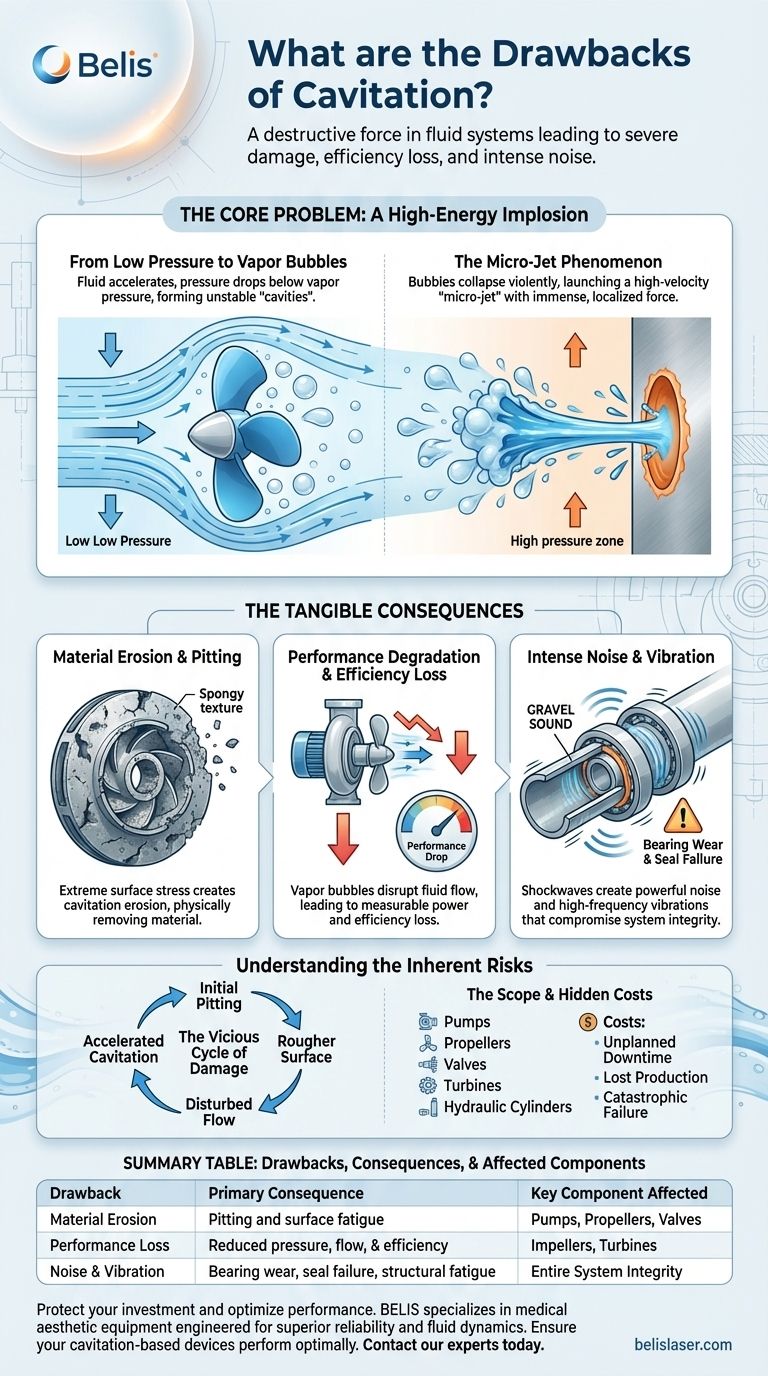

The Core Problem: A High-Energy Implosion

At its heart, cavitation is a phase-change phenomenon driven by pressure dynamics. Understanding this mechanism is key to recognizing its destructive potential.

From Low Pressure to Vapor Bubbles

When a liquid accelerates, such as around a propeller blade or through the eye of a pump impeller, its pressure can drop significantly. If the pressure falls below the liquid's vapor pressure, the liquid essentially boils at a low temperature, forming pockets of vapor, or "cavities."

The Micro-Jet Phenomenon

These vapor bubbles are unstable and flow with the liquid. As they move into an area of higher pressure, they collapse. Near a solid surface, this collapse is asymmetrical, creating a high-velocity "micro-jet" of liquid that impacts the surface with immense, localized force.

This repeated, high-frequency hammering is the direct cause of most cavitation-related damage.

The Tangible Consequences of Cavitation

The energy released by collapsing bubbles manifests in several highly detrimental ways, moving from a microscopic event to a macroscopic system failure.

Material Erosion and Pitting

The most recognized drawback is the physical destruction of components. The micro-jet impacts create extreme surface stress, leading to fatigue failure on a microscopic scale.

This process, known as cavitation erosion, physically removes material, creating a characteristic pitted or spongy appearance. The damage is often concentrated in specific areas where pressure recovery occurs.

Performance Degradation and Efficiency Loss

Vapor bubbles disrupt the smooth, designed flow of liquid across a component's surface. On a pump impeller or propeller, this bubble-filled flow pattern prevents the blades from imparting energy to or extracting energy from the fluid effectively.

The result is a measurable drop in performance. A pump will generate less pressure and flow, while a propeller will produce less thrust. This translates directly to wasted energy and reduced system efficiency.

Intense Noise and Vibration

The shockwaves generated by millions of collapsing bubbles create a distinct and powerful noise, often described as sounding like gravel or marbles passing through the system.

This isn't just an audible nuisance. The energy creating that sound also manifests as high-frequency vibration. This vibration can lead to bearing wear, seal failure, and fatigue cracks in surrounding pipes and support structures.

Understanding the Inherent Risks

Ignoring the signs of cavitation is a significant technical and financial risk. The problem is often progressive and its consequences extend beyond a single component.

The Vicious Cycle of Damage

Initial cavitation pitting creates a rougher surface. This rough texture can disturb the flow further, creating more low-pressure zones and, in turn, accelerating the rate of cavitation and subsequent damage.

The Scope of the Problem

While commonly associated with pumps and propellers, cavitation is a critical concern in many other hydraulic components. Control valves, turbines (including renewable energy sources like tidal stream turbines), and even the passages within hydraulic cylinders can all suffer from its effects.

The Hidden Costs of Inaction

The true cost of cavitation goes beyond replacing a damaged impeller. It includes the expense of unplanned downtime, lost production or operational capacity, and the potential for a catastrophic failure that could damage more expensive parts of the system.

Making the Right Choice for Your Goal

Addressing cavitation requires a clear understanding of your primary objective, whether it's designing a new system, operating existing equipment, or diagnosing a problem.

- If your primary focus is equipment longevity: Ensure the system pressure at the pump inlet (NPSHa) always exceeds the pump's requirement (NPSHr) and select cavitation-resistant materials like stainless steel or bronze for critical components.

- If your primary focus is system performance: Operate equipment within its designed best efficiency point (BEP) and analyze the fluid path to eliminate sharp turns or restrictions that cause abrupt pressure drops.

- If your primary focus is diagnostics and maintenance: Listen for the characteristic crackling noise, monitor for unexplained vibrations, and schedule regular inspections of susceptible components for any signs of pitting.

Proactively managing fluid dynamics is the only effective way to mitigate the destructive impact of cavitation.

Summary Table:

| Drawback | Primary Consequence | Key Component Affected |

|---|---|---|

| Material Erosion | Pitting and surface fatigue | Pumps, Propellers, Valves |

| Performance Loss | Reduced pressure, flow, and efficiency | Impellers, Turbines |

| Noise & Vibration | Bearing wear, seal failure, structural fatigue | Entire System Integrity |

Protect your investment and optimize performance. The destructive effects of cavitation can lead to costly downtime and equipment failure. BELIS specializes in providing professional medical aesthetic equipment engineered for superior reliability and fluid dynamics. If you operate medical aesthetics clinics or premium beauty salons, ensuring your cavitation-based devices perform optimally is critical. Contact our experts today to learn how our solutions can enhance your equipment's longevity and efficiency.

Visual Guide

Related Products

- Ultrasonic Cavitation Radiofrecuency Machine for Body Slimming

- Cryolipolysis Fat Freezing Machine and Ultrasonic Cavitation Device

- Cryolipolysis Fat Freezing Machine Ultrasonic Cavitation Fat Reducing Device

- Cryolipolysis Cavitation Machine Fat Cavitation Machine

- Cryolipolysis Fat Freezing Cavitation Lipo Laser Machine

People Also Ask

- How does ultrasonic cavitation compare to Cryolipolysis? Choosing the Best Non-Invasive Body Contouring Method

- Can you use a cavitation machine every day? Why Less is More for Better Results

- What is the principle behind using ultrasound for noninvasive fat reduction? Master the Science of Body Contouring

- Can ultrasonic cavitation be performed during menstruation? Key Safety Guidelines for Best Results

- Are the results of ultrasonic cavitation permanent? Unlock Long-Term Body Sculpting Success

- What is vacuum-cavitation therapy? Discover Non-Invasive Fat Reduction & Body Sculpting Secrets

- What other treatments can be combined with ultrasonic cavitation? Maximize Results with Synergistic Therapies

- What are the restrictions for cavitation? Ensure Your Safety and Treatment Success