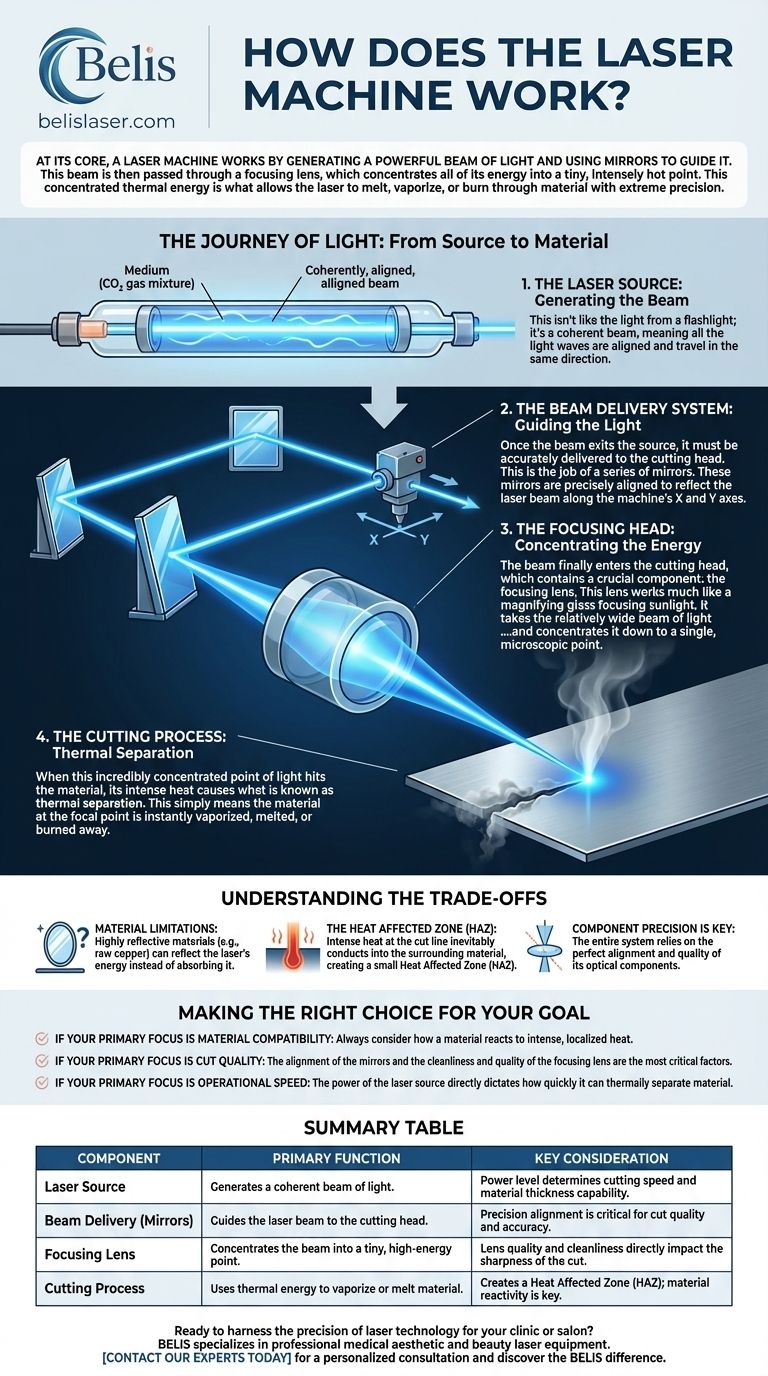

At its core, a laser machine works by generating a powerful beam of light and using mirrors to guide it. This beam is then passed through a focusing lens, which concentrates all of its energy into a tiny, intensely hot point. This concentrated thermal energy is what allows the laser to melt, vaporize, or burn through material with extreme precision.

The fundamental principle is not mechanical force, but the precise control and concentration of light energy. The machine transforms electricity into a coherent light beam, guides it, and focuses it to create a thermal tool capable of cutting materials.

The Journey of Light: From Source to Material

Understanding a laser cutter is best done by following the path of the light beam itself, from its creation to the moment it contacts the material. Each component plays a critical role in shaping and directing this energy.

The Laser Source: Generating the Beam

The process begins in the laser tube or resonator. This is the heart of the machine. Inside, a medium (like a CO2 gas mixture) is stimulated with energy, causing it to emit a special, highly organized beam of light.

This isn't like the light from a flashlight; it's a coherent beam, meaning all the light waves are aligned and travel in the same direction.

The Beam Delivery System: Guiding the Light

Once the beam exits the source, it must be accurately delivered to the cutting head. This is the job of a series of mirrors.

These mirrors are precisely aligned to reflect the laser beam along the machine's X and Y axes. As the cutting head moves, the mirrors ensure the beam remains perfectly aimed at its target.

The Focusing Head: Concentrating the Energy

The beam finally enters the cutting head, which contains a crucial component: the focusing lens. This lens works much like a magnifying glass focusing sunlight.

It takes the relatively wide beam of light from the mirrors and concentrates it down to a single, microscopic point. This act of concentration dramatically increases the energy density.

The Cutting Process: Thermal Separation

When this incredibly concentrated point of light hits the material, its intense heat causes what is known as thermal separation.

This simply means the material at the focal point is instantly vaporized, melted, or burned away. The machine moves the cutting head to create a continuous cut, effectively tracing a design by removing material.

Understanding the Trade-offs

While powerful, the thermal nature of laser cutting has inherent limitations and side effects that are important to understand for achieving high-quality results.

Material Limitations

Not all materials react to heat in the same way. Highly reflective materials, like raw copper or brass, can be difficult to cut because they reflect much of the laser's energy instead of absorbing it.

The Heat Affected Zone (HAZ)

The intense heat at the cut line inevitably conducts into the surrounding material. This creates a small border known as the Heat Affected Zone (HAZ), where the material's properties may be slightly altered.

For most applications, this zone is negligible, but for high-precision components, it is a critical factor to manage.

Component Precision is Key

The entire system relies on the perfect alignment and quality of its optical components. A misaligned mirror or a low-quality lens will result in a less focused beam, leading to poor cut quality, wider kerfs (the width of the cut), and reduced power.

Making the Right Choice for Your Goal

Understanding how the laser works allows you to make better decisions based on your project's specific needs.

- If your primary focus is material compatibility: Always consider how a material reacts to intense, localized heat.

- If your primary focus is cut quality: The alignment of the mirrors and the cleanliness and quality of the focusing lens are the most critical factors.

- If your primary focus is operational speed: The power of the laser source directly dictates how quickly it can thermally separate material, thus determining the maximum cutting speed.

By seeing the laser not as a brute-force tool but as a system for precisely controlling energy, you gain true command over the entire process.

Summary Table:

| Component | Primary Function | Key Consideration |

|---|---|---|

| Laser Source | Generates a coherent beam of light. | Power level determines cutting speed and material thickness capability. |

| Beam Delivery (Mirrors) | Guides the laser beam to the cutting head. | Precision alignment is critical for cut quality and accuracy. |

| Focusing Lens | Concentrates the beam into a tiny, high-energy point. | Lens quality and cleanliness directly impact the sharpness of the cut. |

| Cutting Process | Uses thermal energy to vaporize or melt material. | Creates a Heat Affected Zone (HAZ); material reactivity is key. |

Ready to harness the precision of laser technology for your clinic or salon?

BELIS specializes in professional medical aesthetic and beauty laser equipment. Our machines are engineered for reliability, superior cut quality, and exceptional results on a wide range of applications. Whether you serve a medical aesthetics clinic or a premium beauty salon, we have the right solution to enhance your services and grow your business.

Contact our experts today for a personalized consultation and discover the BELIS difference.

Visual Guide

Related Products

- Fractional CO2 Laser Machine for Skin Treatment

- Cryolipolysis Fat Freezing Machine Cavitation Lipo Laser Machine

- Pico Picosecond Laser Machine for Tattoo Removal Picosure Pico Laser

- Cryolipolysis Fat Freezing Cavitation Lipo Laser Machine

- Clinic Use IPL SHR ND YAG Laser Hair Removal RF Skin Tightening Machine

People Also Ask

- What will my face look like after a CO2 laser? Your Complete Recovery Timeline

- Who is not a good candidate for CO2 laser? Avoid Complications and Ensure Safe Treatment

- Why am I not seeing results after a CO2 laser? Your Patience is the Key to Long-Term Skin Rejuvenation

- What is a fractional CO2 laser machine used for? A Guide to Advanced Skin Resurfacing

- What is the downside of a CO2 laser? Weighing Dramatic Results Against Downtime & Risks