At its core, a laser level works by projecting a highly focused beam of light that has been precisely oriented to gravity. It uses a laser diode to create the light and an internal mechanism, typically a pendulum, to ensure that the projected beam is perfectly level (horizontal) or plumb (vertical).

The true innovation in a modern laser level is not just the laser itself, but the self-leveling system within it. This mechanism uses gravity to automatically position the laser, removing human error and guaranteeing a perfectly true reference line.

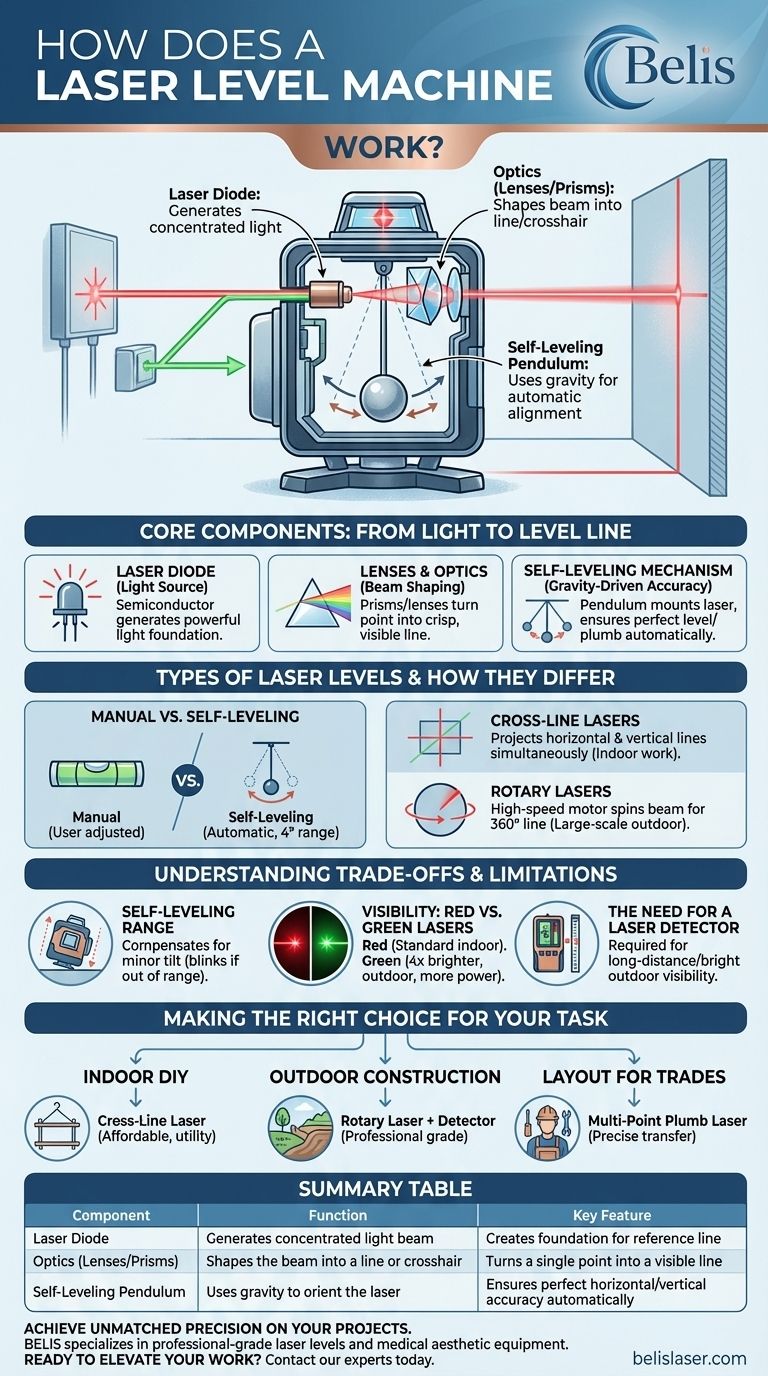

The Core Components: From Light to Level Line

To understand how a laser level achieves such precision, we must look at its three critical internal components: the laser source, the optics that shape the beam, and the leveling mechanism that orients it.

The Laser Diode: The Source of Light

Everything begins with a laser diode, a small semiconductor device similar to an LED. This diode generates a concentrated, powerful beam of light, which serves as the foundation for the reference line.

Lenses and Optics: Shaping the Beam

A raw laser beam is just a single point of light. To be useful for leveling, this dot must be transformed into a line. The beam passes through specialized lenses or prisms that spread the light horizontally or vertically, turning the single point into a crisp, visible line on a surface.

The Self-Leveling Mechanism: The Heart of Accuracy

This is where the precision comes from. The entire laser and lens assembly is mounted on a pendulum, which is precisely weighted and balanced. Due to gravity, this pendulum will always hang perfectly plumb (vertically).

By mounting the laser on this stable, gravity-oriented platform, the device ensures that any horizontal line it projects is perfectly level, and any vertical line is perfectly plumb. This system compensates for the tool being on a slightly unlevel surface.

Types of Laser Levels and How They Differ

While the core principle is the same, different tasks require different types of laser projection. The mechanism changes slightly to achieve these results.

Manual vs. Self-Leveling

The most basic distinction is how the tool is initially leveled. Manual levels require the user to adjust the device using traditional bubble vials. Self-leveling models, which are now the standard, use the internal pendulum to do this automatically within a certain range (typically around 4 degrees).

Cross-Line Lasers

These are the most common type for indoor work like installing cabinets or hanging pictures. They use the pendulum system and fixed lenses to project both a horizontal and a vertical line simultaneously, creating a perfect crosshair.

Rotary Lasers

Designed for large-scale projects like grading land or installing foundations, rotary lasers work differently. They project a single dot of light, but a high-speed motor spins the prism or mirror that directs it, typically at over 600 RPM. This rapid rotation creates a full 360-degree line of light around the entire worksite.

Understanding the Trade-offs and Limitations

A laser level is a precision instrument, and understanding its limitations is key to using it effectively.

The "Self-Leveling" Range

A self-leveling mechanism can only compensate for a small amount of tilt. If the device is placed on a surface that is too sloped (usually more than 4 degrees), the pendulum cannot settle correctly. To prevent you from using an inaccurate line, the laser will typically blink or shut off entirely.

Visibility: Red vs. Green Lasers

The color of the laser matters for visibility. Red lasers are the traditional standard and are perfectly adequate for most indoor work. Green lasers, however, appear up to four times brighter to the human eye and are far easier to see in bright indoor conditions or over longer distances. The trade-off is that green lasers are more complex, consume more battery power, and are more expensive.

The Need for a Laser Detector

In bright outdoor sunlight or when using a rotary laser over a long distance, the laser line becomes completely invisible to the naked eye. For these applications, a separate handheld device called a laser detector is required. You move the detector up and down a grade rod until it beeps, signaling it has found the exact location of the invisible laser line.

Making the Right Choice for Your Task

Selecting the correct laser level depends entirely on the job you need to accomplish.

- If your primary focus is indoor DIY projects: A self-leveling cross-line laser offers the best combination of utility and affordability for tasks like hanging shelves, aligning tiles, or installing trim.

- If your primary focus is large outdoor construction: A rotary laser paired with a detector is the only professional solution for establishing level grades across a wide area.

- If your primary focus is layout for trades (plumbing, electrical): A multi-point or "plumb" laser is ideal, as it projects precise dots to transfer points from the floor to the ceiling with perfect accuracy.

Understanding how this tool leverages gravity empowers you to select and use it with complete confidence.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Laser Diode | Generates the concentrated light beam | Creates the foundation for the reference line |

| Optics (Lenses/Prisms) | Shapes the beam into a line or crosshair | Turns a single point into a visible line |

| Self-Leveling Pendulum | Uses gravity to orient the laser | Ensures perfect horizontal/vertical accuracy automatically |

Achieve Unmatched Precision on Your Projects

BELIS specializes in professional-grade laser levels and medical aesthetic equipment, serving medical aesthetics clinics and premium beauty salons. Our tools deliver the accuracy and reliability your business demands.

Ready to elevate your work? Contact our experts today to find the perfect laser solution for your specific needs.

Visual Guide

Related Products

- Diode Laser SHR Trilaser Hair Removal Machine for Clinic Use

- Clinic Diode Laser Hair Removal Machine with SHR and Trilaser Technology

- Pico Picosecond Laser Machine for Tattoo Removal Picosure Pico Laser

- Trilaser Diode Hair Removal Machine for Beauty Clinic Use

- Diode Tri Laser Hair Removal Machine for Clinic Use

People Also Ask

- Why is it necessary to monitor skin surface temperature during laser lipolysis? Ensure Patient Safety & Results

- How does the cumulative process of medical aesthetic devices benefit skin management? Unlock Long-Term Skin Stability

- What are the causes of fine superficial wrinkles in the skin? Uncover the Root Biological & Environmental Factors

- What factor can affect the effectiveness of laser treatment for telangiectasia? Understanding Key Success Variables

- How do medical-grade LED radiation devices and photosensitizers work in PDT? Unlock New Fungal Infection Solutions

- What role does an NTC thermistor characteristic table play in temperature control logic? Boost Precision and Speed

- What is the physical mechanism behind vaporization ablation? Mastering Laser-Tissue Interaction for Clinics

- What advantages do optical fiber bundles provide in controlling depth of thermal penetration? Mastering Precision.