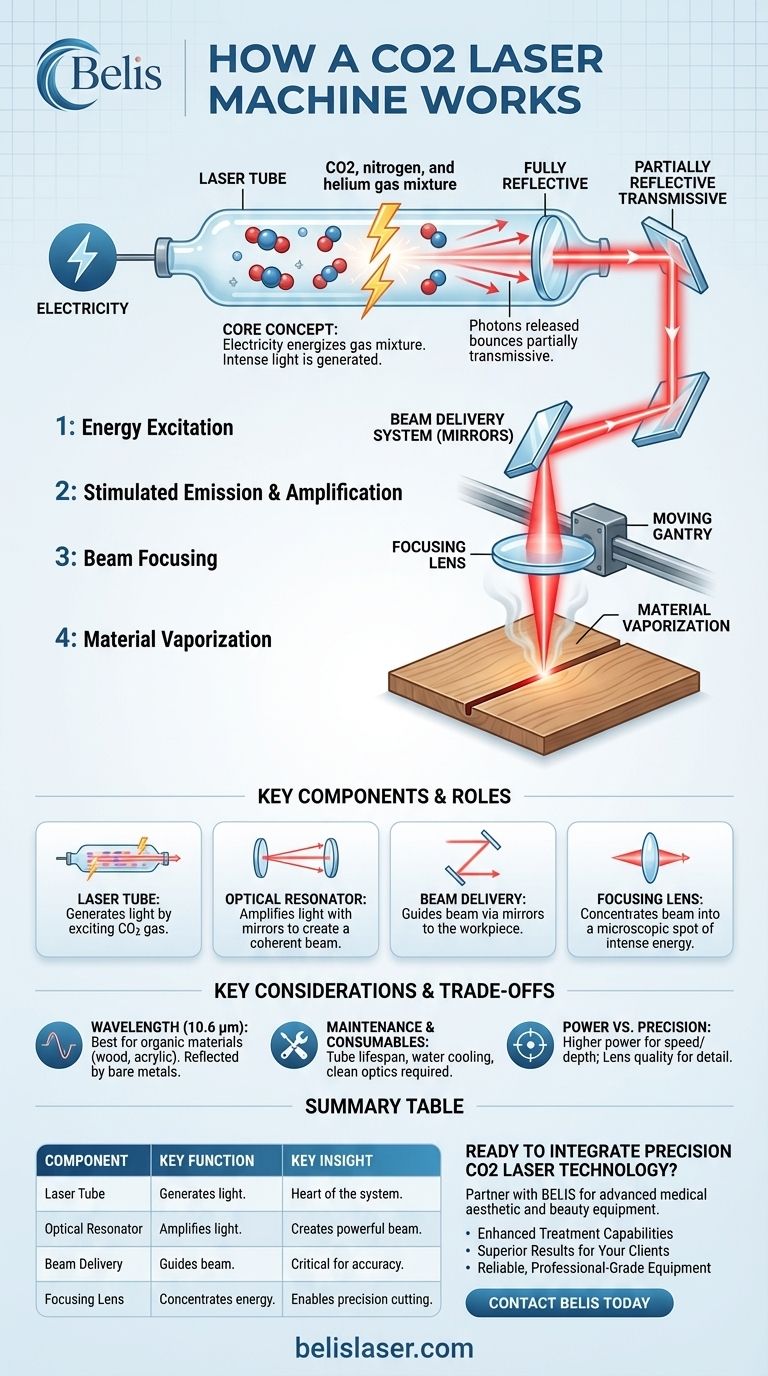

At its core, a CO2 laser works by using electricity to energize a gas mixture inside a sealed tube. This creates an intense beam of light, which is then amplified and focused by a series of mirrors and a lens. This focused beam contains immense thermal energy, allowing it to precisely vaporize, melt, or burn away material.

A CO2 laser is not just a light source; it's a system for generating, amplifying, and delivering highly controlled thermal energy. Understanding this process—from the gas in the tube to the final focused spot—is the key to mastering its capabilities.

The Core Components and Their Roles

To truly understand how a CO2 laser functions, we must look at the four critical systems that work in concert: the laser tube, the optical resonator, the beam delivery system, and the focusing lens.

The Laser Tube: Where Light is Born

The heart of the machine is a sealed glass tube containing a specific gas mixture, primarily composed of carbon dioxide (CO2), nitrogen, and helium. When high-voltage electricity is applied, it excites the nitrogen molecules, which then transfer their energy to the CO2 molecules. As these CO2 molecules drop back to a lower energy state, they release photons—particles of light.

The Optical Resonator: Amplifying the Light

At each end of the laser tube is a mirror, forming an "optical resonator." One mirror is fully reflective, while the other is partially transmissive, meaning it reflects most light but allows a small percentage to pass through.

The photons generated in the tube bounce back and forth between these mirrors thousands of times. As they travel, they stimulate other excited CO2 molecules to release identical photons, creating a cascading amplification of perfectly synchronized light. This creates a coherent and powerful laser beam.

The Beam Delivery System: Guiding the Energy

Once the laser beam gains sufficient intensity, it exits the tube through the partially transmissive mirror. A series of three or more precisely aligned mirrors then guides this beam from the back of the machine to the moving gantry and finally down to the workpiece. The precise alignment of these mirrors is critical for maintaining power and accuracy.

The Focusing Lens: Concentrating the Power

The final component in the beam's path is the focusing lens. Much like a magnifying glass can focus sunlight to a point, this lens takes the relatively wide laser beam (around 5-7mm) and concentrates all its energy into a microscopic spot. This extreme concentration of energy is what gives the laser its ability to cut and engrave with incredible precision.

The Process: From Light to Cut

The entire operation can be broken down into a sequence of events that happen almost instantaneously.

Step 1: Energy Excitation

Electricity charges the gas mixture in the laser tube, creating a population of high-energy CO2 molecules ready to release their stored energy as light.

Step 2: Stimulated Emission and Amplification

A few photons are spontaneously released, triggering a chain reaction of "stimulated emission" as they bounce between the mirrors. This builds the intensity and coherence of the laser beam inside the tube.

Step 3: Beam Focusing

The now-powerful beam exits the tube and is guided by mirrors to the focusing lens, which concentrates its energy onto the material's surface.

Step 4: Material Vaporization

The intense thermal energy at the focal point instantly heats the material to its vaporization point. The machine's motion control system moves this focal point along a programmed path to create the desired cut or engraving.

Understanding the Trade-offs and Key Considerations

While powerful, CO2 lasers are not a universal solution. Understanding their characteristics is key to using them effectively.

Wavelength and Material Compatibility

CO2 lasers produce light at a wavelength of 10.6 micrometers (10,600nm). This wavelength is highly absorbed by organic materials like wood, acrylic, leather, paper, and fabric, making it the perfect tool for these applications. However, this same wavelength is highly reflected by bare metals, making CO2 lasers unsuitable for cutting or deep-engraving them without special coatings.

Maintenance and Consumables

The laser tube has a finite lifespan (typically 1,500 to 10,000 hours) and is a significant consumable cost. The system also generates immense heat and requires a water cooling system to prevent overheating. Finally, the mirrors and lens must be kept perfectly clean; any dust or residue can absorb energy, reducing power and potentially damaging the optics.

Power vs. Precision

Laser power, measured in watts, directly impacts cutting speed and thickness. A higher wattage (e.g., 100W) will cut through thick material much faster than a lower wattage (e.g., 40W). However, fine engraving detail is often more dependent on the quality of the focusing lens and the machine's motion system than on raw power.

Making the Right Choice for Your Goal

Understanding the mechanics allows you to select the right tool and approach for your specific project.

- If your primary focus is high-detail engraving on wood or leather: A lower-wattage CO2 laser (40-60W) with a high-quality lens offers excellent precision and is highly cost-effective.

- If your primary focus is cutting thicker acrylic or wood for production: A higher-wattage machine (80-150W) is necessary to achieve the speed and cutting depth required.

- If your primary focus is marking or cutting bare metals: A CO2 laser is the wrong tool; you should investigate a fiber laser, which operates at a wavelength that is readily absorbed by metals.

By understanding how a CO2 laser transforms electricity into a focused point of energy, you can better diagnose issues, optimize settings, and achieve your desired results.

Summary Table:

| Component | Key Function | Key Insight |

|---|---|---|

| Laser Tube | Generates light by exciting a CO2 gas mixture. | Heart of the system; gas mixture is key. |

| Optical Resonator | Amplifies light using fully and partially reflective mirrors. | Creates a coherent, powerful laser beam. |

| Beam Delivery | Guides the beam via precisely aligned mirrors to the workpiece. | Critical for maintaining power and accuracy. |

| Focusing Lens | Concentrates the beam into a microscopic spot of intense energy. | Enables precise cutting and engraving. |

Ready to Integrate Precision CO2 Laser Technology?

Understanding the mechanics is the first step. Implementing the right equipment is what drives your business forward. BELIS specializes in professional medical aesthetic and beauty equipment, providing advanced CO2 laser solutions tailored for medical aesthetics clinics and premium beauty salons.

Partner with BELIS to unlock:

- Enhanced Treatment Capabilities: Leverage precise thermal energy for advanced aesthetic procedures.

- Superior Results for Your Clients: Achieve clean, accurate outcomes that build trust and satisfaction.

- Reliable, Professional-Grade Equipment: Invest in durable systems designed for clinical and salon environments.

Contact BELIS today to discuss how our CO2 laser machines can become a cornerstone of your service offerings.

Visual Guide

Related Products

- Fractional CO2 Laser Machine for Skin Treatment

- Fractional CO2 Laser Machine for Skin Treatment

- Cryolipolysis Fat Freezing Machine Cavitation Lipo Laser Machine

- Pico Picosecond Laser Machine for Tattoo Removal Picosure Pico Laser

- Cryolipolysis Fat Freezing Cavitation Lipo Laser Machine

People Also Ask

- Is CO2 laser for all skin types? A Critical Guide to Skin Type Safety and Risks

- Why am I not seeing results after a CO2 laser? Your Patience is the Key to Long-Term Skin Rejuvenation

- What is a CO2 fractional laser good for? Dramatic Skin Rejuvenation for Wrinkles & Scars

- What is a fractional CO2 laser machine used for? A Guide to Advanced Skin Resurfacing

- What is the downside of a CO2 laser? Weighing Dramatic Results Against Downtime & Risks